- Wrench emits a click that can be heard and felt when the preset value is reached

- High-contrast dual-range scale is easy to read, even in low light

- Reversible ratchet head drives in both directions and measures torque in clockwise direction

- Durable all-steel construction has no plastic parts to break or wear out

- Ships pre-calibrated to +/- 4% accuracy and ready to use

Calibrated to an accuracy of +/- 4%, the TEKTON 1/4 in. Drive Click Torque Wrench lets you work with confidence, eliminating guessing and the common tendency to overtighten fasteners. Correctly tightening fasteners to a vehicle or equipment manufacturer's torque specifications ensures parts are properly secured without being damaged. Simple and easy to use, this wrench has a reversible ratcheting head that drives fasteners in both directions and measures torque in the clockwise direction. To measure torque, set the desired value on the handle scale (inch pounds or Newton meters) and begin tightening the fastener. When the preset torque value is reached, a reliable mechanical operation inside the handle produces a click you can hear and feel, alerting you to stop applying force. Built for consistent performance and years of dependable service, the mechanical design doesn't need batteries, and the all-steel construction has no plastic parts to break or wear out.

IMPORTANT: This wrench is shipped pre-calibrated and ready to use. To help maintain calibration, store at its lowest setting of 20 in.-lb./2.2 Nm when not in use. Be sure to read and understand the operator's manual, including all safety information, before first use.

Includes:

- (1) 1/4 in. drive torque wrench

- (1) Storage case

- Operator's manual with torque conversion chart

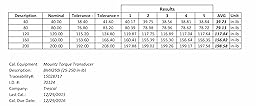

By zeromajin

I had the opportunity to accurately test this product on a torque transducer. I documented the results for others to consider.

This product performed exceptionally well out of the box. Tested with a 1.5% average tolerance. Product is rated as +/- 4%.

Will test again after 6 months of use and proper storage to see how well it keeps its calibration.

This product performed exceptionally well out of the box. Tested with a 1.5% average tolerance. Product is rated as +/- 4%.

Will test again after 6 months of use and proper storage to see how well it keeps its calibration.

By Robert M. Koretsky

I bought this torque wrench to accurately secure 11 nuts that hold down the faceplate on my Weil Mclain Ultra 3 - 155 gas boiler heat exchanger, and it did the job perfectly. I read the instructions, and was careful to first test the operation of the tool at the low torque setting of 50 inch pounds on a nut and stud in my bench vise. This gave me the feel for how the click action actually worked at that setting. Unlike other foot pound torque wrenches I've used in the past, this wrench only clicks very noticeably when you reach the desired torque, and then does not release, but keeps on allowing you to go beyond the desired setting. Once you have the feel for it, it's easy to not over torque anything.

Very well made tool, beautiful finish and case that protects it. When storing, make sure to set it to the lowest torque setting to relax the spring and keep it accurate.

Very well made tool, beautiful finish and case that protects it. When storing, make sure to set it to the lowest torque setting to relax the spring and keep it accurate.

By Derrick Wilson

Great inch pounds torque wrench. It is a mini version of a foot pounds wrench. I bought it for gunsmithing to torque stocks on to actions, scope bases and rings. It is very accurate. I tested it with my adult son's several hundred dollar wrench and it was 1/10th inch pounds less. His wrench does 1/10ths inch pounds with a dial. I do put it back to zero every time I get done using it. My wrench does newton's but I have not needed that scale yet. If you have not set a torque wrench in a while make sure you refresh you memory for great results.

You don't want anything to shift when the bull of a lifetime is in your scope and more importantly you want the harmonics of your rifle to cause a bad shot.

I bought the Tekton Everybit 135 piece set to compliment this torque wrench.

You don't want anything to shift when the bull of a lifetime is in your scope and more importantly you want the harmonics of your rifle to cause a bad shot.

I bought the Tekton Everybit 135 piece set to compliment this torque wrench.

By Jamie Smart

This is a good wrench. Construction is just like it's bigger ft lb brothers. I think a lot of the negative ratings are because people think this is a ft lb wrench, it's not, it's in lbs. The break is a bit more subtle since the torque is so much less. I suspect I will have this wrench forever. I would recommend this wrench for anyone who wants a quality tool for a fair price.

By S J Harman

At under $50, with an accuracy spec the same or very near torque wrenches costing much more, and quality of construction that couldn't be better, this wrench is a bargain. If the range (20 - 200 in/lb) meets your needs, you can't go wrong. I use it to work on my bicycle and it's perfect. This is a dual scale wrench. If you like torque values in N/m, then a little math is required to set the wrench properly. The increments on the vernier dial end up being an odd value, and the markings on the main scale are odd values as well. However, I use in/lb exclusively and that scale is very straight-forward. If you have N/m torque values it's easy enough to convert them to in/lb. In fact, I made a table of the torque values on my bike and expressed them all in in/lb so I don't use the N/m scale at all. Great tool for the money!

By A. Aurelius

About eight years ago, I purchased my first dual suspension carbon fiber mountain bike which also has a carbon fiber handlebar and seatpost. I enjoyed the bike so much, I purchased another for all mountain riding a few years later and then, last year, one for my wife. The only problem with carbon bikes though (or carbon fiber in general) is that you have to be very careful when torquing components because carbon will not deform like a metal that is over stressed. Carbon fiber is extremely sensitive to point stress and compression loads and if you surpass the torque limit of the material it will snap or fracture suddenly (often, without the owner noticing). And that is where the Tekton 24320 comes in. This 1/4 inch drive socket torque wrench is ideal for that 2 to 22 Newton Meters (Nm) range that applies to most fasteners on a mountain bike, and to make sure undue stress is not being applied to the carbon fiber frame or components.

My Tekton 24320 came just fine a week after ordering , and as soon as I received my wrench, I set it up in my vise to do an accuracy test. I attached a plumb weight (of known mass) from a string on the end and began dialing the lock ring back down to 4 N m, until the weight made it click. I was checking to see if it clicked at 4 Nm (35 inch pounds), because this is what Easton recommends for my EC90 SL riser bar when mated to my Thomson Elite four bolt stem. I then measured the distance (from the center of the drive to the center of the handle where the string was tied holding the weight) x weight I used and then converted to Newton Meters, and compared that to the setting at which it had clicked. It turns out the Tekton 24320 is accurate to 1.1%. However, these type of torque wrenches are more accurate when the internal spring is stretched than when it is relaxed, so a further 1 or 2% correction could be in order either way. (you have to consider dynamic versus static loading when conducting testing) Still, a deviance of only 1.1% is well within the 4% Tekton claims and is very accurate for a torque wrench in this price range.

The Tekton 24320 also has some nice features I really enjoy. The printed scale on the handle is easy to read. The knurled handle is easy to hold and is solid steel rather than the plastic of some other torque wrenches. Also, the feel of the Tekton 24320 is much more intuitive during dynamic loading and when you reach the limit in torque you set, the click and swivel of the head is sharp, loud and easy to notice due to the roller pin rolling over the roller bearing. This is a welcome feature when you are wrenching and torquing multiple fasteners quickly. Overall, the Tekton 24320 feels high-end and has a high quality of construction with more steel used throughout compared to many competitors. To top it off, the Tekton 24320 has a port in the center of the main shaft for resetting it back to 100% accuracy after you use it for several years. (or, if you misuse it) The only aspect I do not like about the Tekton 24320 for bicycle use at least, is that it cannot register torque in both directions (for right and left handed threads). That said, on modern bikes, you typically only find left handed threads in three places; the left pedal, the right bottom bracket cup and the freewheel cone. And, the left pedal and right BB cup require more torque than the Tekton 24320 can measure anyway.

And finally, there is the price. The Tekton 24320 sells for $38 compared to $70 to $180 for many other competitors that are similarly constructed. That is simply a huge amount of difference and when you combine that with the fact that the Tekton 24320 is so accurate, it makes deciding which model to purchase, easy.

So far, I have had my Tekton 24320 for about seven months and have used it not only on my bikes but also with some light auto work, and the wrench has been both accurate and performed superbly. For me, that equals five stars!

My Tekton 24320 came just fine a week after ordering , and as soon as I received my wrench, I set it up in my vise to do an accuracy test. I attached a plumb weight (of known mass) from a string on the end and began dialing the lock ring back down to 4 N m, until the weight made it click. I was checking to see if it clicked at 4 Nm (35 inch pounds), because this is what Easton recommends for my EC90 SL riser bar when mated to my Thomson Elite four bolt stem. I then measured the distance (from the center of the drive to the center of the handle where the string was tied holding the weight) x weight I used and then converted to Newton Meters, and compared that to the setting at which it had clicked. It turns out the Tekton 24320 is accurate to 1.1%. However, these type of torque wrenches are more accurate when the internal spring is stretched than when it is relaxed, so a further 1 or 2% correction could be in order either way. (you have to consider dynamic versus static loading when conducting testing) Still, a deviance of only 1.1% is well within the 4% Tekton claims and is very accurate for a torque wrench in this price range.

The Tekton 24320 also has some nice features I really enjoy. The printed scale on the handle is easy to read. The knurled handle is easy to hold and is solid steel rather than the plastic of some other torque wrenches. Also, the feel of the Tekton 24320 is much more intuitive during dynamic loading and when you reach the limit in torque you set, the click and swivel of the head is sharp, loud and easy to notice due to the roller pin rolling over the roller bearing. This is a welcome feature when you are wrenching and torquing multiple fasteners quickly. Overall, the Tekton 24320 feels high-end and has a high quality of construction with more steel used throughout compared to many competitors. To top it off, the Tekton 24320 has a port in the center of the main shaft for resetting it back to 100% accuracy after you use it for several years. (or, if you misuse it) The only aspect I do not like about the Tekton 24320 for bicycle use at least, is that it cannot register torque in both directions (for right and left handed threads). That said, on modern bikes, you typically only find left handed threads in three places; the left pedal, the right bottom bracket cup and the freewheel cone. And, the left pedal and right BB cup require more torque than the Tekton 24320 can measure anyway.

And finally, there is the price. The Tekton 24320 sells for $38 compared to $70 to $180 for many other competitors that are similarly constructed. That is simply a huge amount of difference and when you combine that with the fact that the Tekton 24320 is so accurate, it makes deciding which model to purchase, easy.

So far, I have had my Tekton 24320 for about seven months and have used it not only on my bikes but also with some light auto work, and the wrench has been both accurate and performed superbly. For me, that equals five stars!

By jim d

Wrench has a very solid feel and smooth action. Customer support is outstanding! When I got the wrench I found it was not calibrated to specification. Called Tekton/MIT tool customer support and representative Dave was extremely helpful. We verified the problem and he offered to immediately send me a replacement. Wrench accuracy is now either dead on or at the most barely 1% off depending on the torque setting. That's as good as wrenchs 4-5 times more expensive. I'm very pleased with the wrench and the customer support and at these prices plan on adding the 3/8 and 1/2 torque wrenches to my tool chest also.

By Douglas Kivett

Great for what I need it for. I do a lot of my own wrenching on my motorcycles and my daily driver. But I'm not a certified mechanic or trying to make a living at it. I consider myself an above average wrench and I have good enough "feel" for most fasteners. However, on certain jobs, like valve cover bolts and such, you really need to take the guess work out of it. These torque wrenches seem to be of good quality build, they feel good in the hand, and they perform well. No complaints. Honestly, what sold me on this brand in particular (aside from the numerous positive reviews) is Tekton's customer service. They respond to pretty much ANY negative reviews on Amazon and they seem to do what it takes to make things right. That plus a lifetime warranty. And they're good, quality torque wrenches. I am very happy with my purchase.

By Brian H

I purchased the wrench to torque some bolts to 20 inch/lbs. The wrench came set to 20in/lbs. I tried it by gripping a 1/4" extension bar in a vice and attaching the wrench to it set at 20in/lbs. It felt like it took a lot of torque to make the wrench click. I confirmed that it took about 80in/lbs of torque to get a click by using a trigger pull spring balance.

I emailed Tektron. Dave responded within 24 hours. He suggested I set the wrench to 100in/lbs and try it. It worked. I reset it to 20in/lbs and it worked as expected. I confirmed this with by trigger pull balance. It clicked at 2.25lbs at 10" of leverage.

The wrench got off to a bit of a rocky start but the customer service saved the day and I would recommend a Tekton torque wrench to a friend.

I emailed Tektron. Dave responded within 24 hours. He suggested I set the wrench to 100in/lbs and try it. It worked. I reset it to 20in/lbs and it worked as expected. I confirmed this with by trigger pull balance. It clicked at 2.25lbs at 10" of leverage.

The wrench got off to a bit of a rocky start but the customer service saved the day and I would recommend a Tekton torque wrench to a friend.

By C. Zachemsky

Bench tested it against known/calibrated torque specs and it was spot on. Nice weight, easy to read, nice distinct "click".

Comments

Post a Comment